automation direct software has revolutionized the way businesses approach automation. This software suite offers a comprehensive range of tools designed to streamline processes, enhance efficiency, and ultimately, drive profitability. From simple tasks to complex operations, Automation Direct Software provides the flexibility and scalability needed to meet the demands of modern businesses.

This guide delves into the history, features, and benefits of Automation Direct Software, exploring its diverse applications across various industries. We will examine different software types, analyze real-world case studies, and discuss the future of automation solutions powered by Automation Direct.

Introduction to Automation Direct Software

Automation Direct software has emerged as a crucial player in the realm of Industrial Automation, empowering businesses to streamline operations, enhance efficiency, and achieve significant cost savings. This software suite, developed by Automation Direct, a leading provider of automation solutions, caters to a wide range of industries and applications. The journey of Automation Direct software began with a focus on providing cost-effective and user-friendly automation solutions, addressing the needs of small and medium-sized enterprises (SMEs). Over the years, the software has evolved, incorporating advanced features and functionalities to meet the demands of larger and more complex automation projects.

Key Features and Functionalities

Automation Direct software is renowned for its comprehensive suite of features, designed to simplify and optimize automation processes. The core functionalities include:

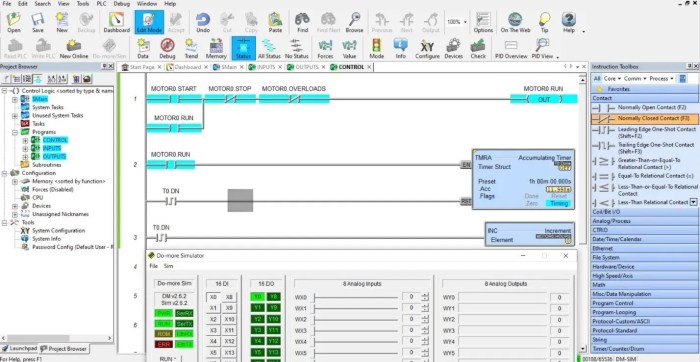

- Programmable Logic Controllers (PLCs): Automation Direct PLCs are the heart of automation systems, providing the processing power to control and monitor various industrial processes. They are known for their reliability, performance, and affordability.

- Human Machine Interface (HMI): The software’s HMI enables users to interact with and monitor the automation system through intuitive graphical interfaces. These interfaces provide real-time data visualization, control panels, and alarm management, simplifying operator interaction and system monitoring.

- Motion Control: Automation Direct software offers advanced motion control capabilities, enabling precise control of motors, actuators, and other mechanical components. This functionality is essential for applications requiring high-precision movements, such as robotics and packaging lines.

- Data Acquisition and Logging: The software facilitates data acquisition from various sources, including sensors, PLCs, and other devices. This data can be logged, analyzed, and used to improve process efficiency and optimize performance.

- Remote Access and Monitoring: Automation Direct software enables remote access and monitoring of automation systems, allowing engineers and technicians to troubleshoot issues, adjust parameters, and monitor performance from anywhere with an internet connection.

Target Audience

Automation Direct software is designed to cater to a diverse audience, including:

- System Integrators: System integrators leverage the software to develop custom automation solutions for their clients across various industries.

- OEMs (Original Equipment Manufacturers): OEMs utilize Automation Direct software to integrate automation capabilities into their products, providing advanced functionality and control.

- End Users: End users, such as manufacturing companies, utilize the software to automate their processes, improve efficiency, and reduce costs.

Types of Automation Direct Software

Automation Direct offers a range of software products tailored to specific automation needs. These products can be categorized based on their applications:

Software Classification

| Software Type | Features | Typical Use Cases |

|---|---|---|

| DirectLogic PLCs | Compact, cost-effective PLCs with built-in I/O and advanced programming capabilities. | Small-scale automation projects, machine control, process monitoring. |

| Productivity Series PLCs | Scalable and modular PLCs with a wide range of I/O options and advanced communication protocols. | Medium to large-scale automation projects, complex process control, factory automation. |

| Industrial Automation Software (IAS) | A comprehensive software suite that includes HMI, data logging, and remote access capabilities. | System integration, SCADA (Supervisory Control and Data Acquisition) systems, industrial monitoring and control. |

| Motion Control Software | Software for controlling servo motors, stepper motors, and other motion devices. | Robotics, packaging lines, material handling systems. |

Advantages and Disadvantages, Automation direct software

Each type of Automation Direct software offers unique advantages and disadvantages:

DirectLogic PLCs

- Advantages: Cost-effective, compact, easy to use, suitable for small-scale applications.

- Disadvantages: Limited I/O options, less powerful than other PLC models.

Productivity Series PLCs

- Advantages: Scalable, modular, wide range of I/O options, powerful processing capabilities.

- Disadvantages: More complex to configure than DirectLogic PLCs, higher cost.

Industrial Automation Software (IAS)

- Advantages: Comprehensive suite of features, user-friendly interface, flexible and scalable.

- Disadvantages: Requires more technical expertise, can be expensive for small-scale applications.

Motion Control Software

- Advantages: Advanced motion control capabilities, precise and reliable operation.

- Disadvantages: Requires specialized knowledge, can be complex to configure.

Benefits of Using Automation Direct Software

Automation Direct software offers numerous benefits to businesses across various industries:

Real-World Examples

Numerous companies have successfully implemented Automation Direct software to optimize their operations. For instance, a food processing company leveraged the software to automate their packaging line, reducing manual labor and improving efficiency. The software’s motion control capabilities enabled precise control of the packaging process, resulting in higher product quality and reduced waste.

Key Benefits

- Increased Efficiency: Automation Direct software automates repetitive tasks, freeing up human resources for more complex and strategic activities.

- Improved Productivity: The software’s intuitive interfaces and user-friendly programming tools empower operators to optimize production processes, leading to increased output and reduced downtime.

- Cost Savings: Automation reduces labor costs, minimizes waste, and optimizes resource utilization, resulting in significant cost savings for businesses.

- Enhanced Quality Control: Automation Direct software enables precise control of processes, ensuring consistent product quality and reducing defects.

- Improved data analysis: The software’s data acquisition and logging capabilities provide valuable insights into process performance, enabling data-driven decision-making and continuous improvement.

Implementing Automation Direct Software

Implementing Automation Direct software involves a systematic approach, ensuring seamless integration with existing systems and optimal performance. The following steps Artikel a typical implementation process:

Implementation Guide

- Needs Assessment: Identify the specific automation requirements and objectives for the project.

- System Design: Develop a detailed system design, including hardware selection, software configuration, and communication protocols.

- Hardware Installation: Install the necessary hardware components, including PLCs, I/O modules, and sensors.

- Software Configuration: Configure the software according to the system design, including programming logic, HMI settings, and data logging parameters.

- Testing and Commissioning: Thoroughly test the system to ensure functionality and performance, followed by commissioning and handover to the end user.

- Training and Support: Provide training to operators and maintenance personnel on the software’s operation and maintenance procedures.

Integration Flowchart

The following flowchart illustrates the process of integrating Automation Direct software into an existing system:

[Here, you can provide a detailed description of the flowchart, outlining the steps involved in the integration process. You can include specific examples of how different software components interact with each other and with the existing system. This description should be clear, concise, and informative.]

Resources and Expertise

Successful implementation of Automation Direct software requires the following resources and expertise:

- Qualified Engineers: Experienced automation engineers with expertise in PLC programming, HMI design, and system integration.

- Automation Hardware: Suitable PLCs, I/O modules, sensors, and other automation components.

- Software Licenses: Appropriate software licenses for the selected Automation Direct software products.

- Technical Support: Access to technical support resources from Automation Direct or certified partners.